Reduced Order Modeling (ROM) in the Field

In a recent blog post, SimuTech Group’s President, Rick James, wrote a high-level overview of Digital Twin, and explained its significant economic impact. Today, SimuTech Group’s Vice President of Test Engineering and QA, Alan McKim, takes a practical view, discussing how–with help from Reduced Order Modeling (ROM)–Digital Twin works in equipment testing. He also illustrates how SimuTech Group used Digital Twin technology to help a customer gain insight and resolve performance concerns.

Though there’s a lot of discussion about Digital Twin technology, some engineers and designers find it difficult to understand how it can economically impact them. Here’s an analogy that might help illustrate the digital twin concept: equipment used in the field could be compared to staff working in a remote location. You need to communicate regularly with these staff members to solve issues. Imagine a staff member dealing with an issue, but not communicating information back to you. This would cause delays, reduced performance, or potentially even ultimate failure of the offsite effort.

In a similar way, equipment has generally been left on its own in the field. However, technology has simplified the ability to gain information about equipment during its operation. Sensors can easily be installed to gather data about temperature, vibration, or load indication–all valuable in determining how the system is performing in its environment. Going back to the analogy: the communication with offsite humans is relatively direct; their communication is understood directly. However, when equipment sends sensor data, this must be interpreted.

Mathematical Reduced Order Modeling (ROM)

This is where mathematical Reduced Order Models (ROMs) come in. With an ROM, you can take the critical aspects of a detailed model and reduce them down to simpler equations or algorithms that can be used in real time. Most engineers are familiar with detailed computer simulations that take hours or days to run. However, with field information, you do not want to wait hours or days to understand the implications. An ROM is the simplification of the input to output of a complex model. You still need the detailed model to generate this relationship, but once it is known, the ROM can be used.

While a Digital Twin is often perceived as a massive undertaking, it doesn’t have to be. Referring back to the analogy of staff working in the field: you may need to deploy a single person, or a group of 100. The same is true for Digital Twin technology, which can be large and broad with lots of details, or narrowly tailored.

At SimuTech Group, we recently performed a Digital Twin analysis that was carefully focused. Our client, a power generation company, was concerned about the life expectancy for new turbine shafts being installed due to an external excitation causing vibrations. These would cause fatigue cycles on the structure and lead to a reduced life. They asked for our help in addressing their concerns in a practical way.

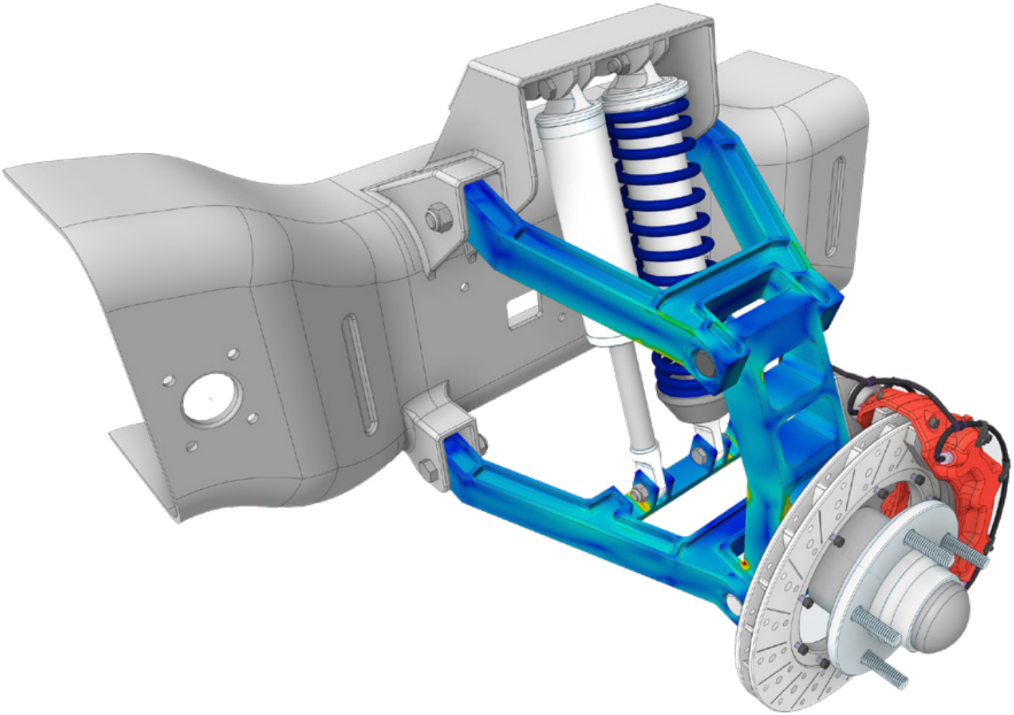

FE Modeling, Fatigue Accumulation & ROMs

Using detailed finite element models and fatigue damage accumulation theory, SimuTech engineers generated ROMs to predict shaft fatigue life. We placed sensors on the turbine shaft to measure vibration. This data was fed back to the ROMs, and an accumulated fatigue was predicted in real-time. Then we developed a simple user interface to give this immediate data back to the operator, which allowed for system operation with confidence of integrity; the customer did not need to take the system down for unneeded inspections.

This particular Digital Twin was employed for a specific requirement, but the same basic process can be employed for a complete system.

When a machine communicates back, engineers and designers can use the information for the next generation of products or improve the product’s current performance via a service call. Either way, Digital Twin data is used to enhance the product and improve customer satisfaction, key economic drivers referred to in our previous blog.

Additional Ansys Software Tips & Tricks Resources

-

- Analyzing normal and Tangential Elastic Foundations in Mechanical

- Why Meshing is Crucial for FEA Fluid Simulations Prior to Prototyping

- For support on Contained Fluid FEA Modeling with HSFLD242 Elements

- For Exporting a Deformed Geometry Shape Post-Analysis in Mechanical

- Moreover, for guidance Multi-Step Analyses in Mechanical

- For Retrieving Beam Reaction Force in a Random Vibration Analysis

- Deploying Ansys Macro Programming vis *USE Command in Mechanical

- For replicating Fatigue Models from Start to Finish in Mechanical

- In addition, setting up Acoustic Simulations of a Silencer

- For a step-by-step guide on 2D to 3D Submodeling in Mechanical

- For modeling Pipe16 Circumferential Stress in Mechanical

- For Support on performing ‘EKILL‘ in Workbench

- APDL Command Objects post-Spectral Analysis

- For Separating DB Database Files from RST Files

- Measuring Geometric Rotation in Mechanical WB

- Explicitly, CAD Geometry Deformation Plasticity

- Offsetting a Temperature Result to Degrees Absolute

- For general guidance on Ansys Post-Processing

- Finally, for basic Ansys Software Installation and License Manager Updates